Matt Lussier from Kidzturn Ministries shows us how they made a fake circular truss. Awesome!

They concentrate on building set elements for their touring kids ministry, but Matt figured this circle-truss work-around might be useful to some churches as well.

They wanted to have two 7 foot circle-truss borders for video screens in their 2011/2012 set. That would have cost about $3000 including freight. This alternative came in at closer to $600.

Materials available at Lowes or Home Depot:

- 200ft spool of black ADS 1″ plastic coil pipe (Made of HDPE)

- Rustoleum hammered metal spray paint or brush on

- Misc screws for assembly

- A couple 10 foot 1″ pvc lengths for crossbars

- Some scrap 3/4 plywood to make connecting plates

Available online:

- Seventy-two 1″ PVS Slip T fittings (they used 36 per side)

Here’s their step by step process:

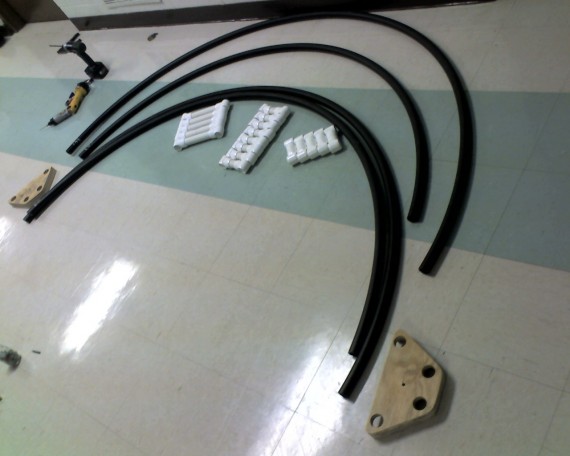

STEP 1 – Cut your black pipe lengths.

With the more complicated 4-pipe, triangular, non-square profile they did, it was a bit complicated to get the 4 perfect lengths. Since they were making 2 identical circle truss elements, they had to try to make 4 equal half trusses. What worked best was to make 4, 2″pvc lengths of the approximate sizes, and shove the black pipe in till it was flush on the other side, then cut.

STEP 2 – Making 4 identical connecting plates.

They used 3/4″ plywood, some wood glue, and some brad nails. The large holes determine the profile of the pipes. The center hole is to bolt the 2 pieces together when completed.

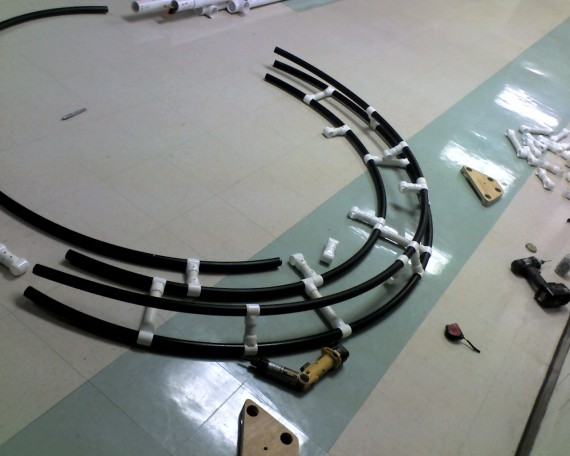

STEP 3 – Screw slip tees on crossbars and get organized before assembly

Cut the 1″ pvc for the quantity of crossbars you want. Screw the slip tees on to the PVC making sure they stay square to each other.

STEP 4 – Assembly – Feed the pipes.

STEP 5 – Line up the crossbars and screw them in place.

Make sure you use your 2 plywood connecting plates on each end. Then start moving all the crossbars in place. Don’t screw them down till you know you got them in their spot.

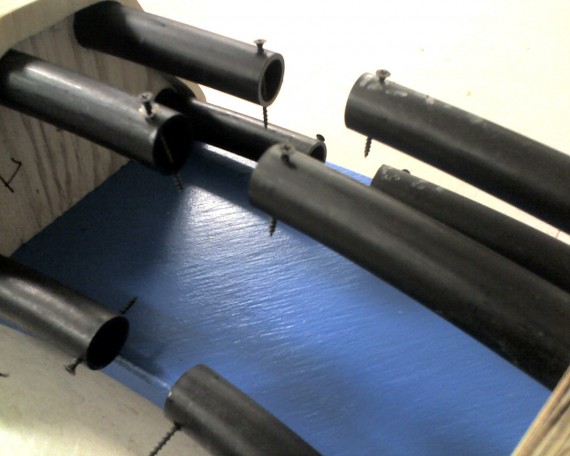

STEP 6 – Trim the excess pipe.

Using the plywood as a guide…make the best judgment call on how much excess pipe needs to be trimmed off. Take your time. If you trim to much, you will need to go back a few steps.

STEP 7 – Add screw “stoppers”.

Matt put 2″ sheetrock screws through the ends.

STEP 8 – Hot glue bases to pipes.

Clamp the pipes so the “stopper” screws are tight against the plywood. Layer on a thick blob of hot glue to permanently seat the plywood on the pipes.

STEP 9 – One half is done…time to repeat.

STEP 10 – Paint silver.

They used rustoleum silver hammered metal brush on paint.

STEP 11 – All done.

STEP 12 – Bolt the 2 halves together at the plywood connector plates.

Notes:

– the size and shape (4 pipe, 3 pipe or 2 pipe) truss will vary the cost.

– this design is to achieve a look, and not to mount lights to.

– they’re strong enough to stretch material on the back and use for front projection or lighting up.

– you can spray them with a chrome silver paint as well for a shinier look.

– this concept shouldn’t stop at a circular truss. Many curved truss stage elements could be faked with this principle.

– remember: this is for decoration and is non-load bearing.

I highly recommend these guys, my other youth pastor friend brought them down to Biloxi, MS and it was awesome. The set was tight too!! Great team.

That is insane.Thanks for providing the detailed pictures. Evenif not going to that extreme it gives some great ideas.

Thanks again!

This is nothing short of brilliant. Wow…some very creative minds at work there! Good stuff!

This has got to be the coolest most retro setup I have ever seen.

This idea would work great for my classic rock band!. I already used the ideas of the white foam board squares and uplighting and they look very cool. Do you have a website, other pics, and such for other parts of the set up as well? Got me pretty excited about trying it. Ok….that’s enuf now.

This theme is a retro rock show vibe.

(i watched a chunk of 80’s concerts on youtube when designing the stage.)…(even a few stryper influences in here) ;)

as we constructed this current set, we upload pictures of the progress here:

http://kidzturn.com/life/?cat=6

there is no explanation of what we are doing and why, but you may be able to soak up some inspiration…

we have also posted an archive (organized by past themes) of set construction pictures here:

http://www.kidzturn.com/kidzturn/index.php?option=com_content&view=article&id=48&Itemid=139

thanks all for the comments…. i’ve always had an open-door policy when it comes to positive feedback. :)

Wow! This looks amazing! What light fixtures are you using?

we run almost 300 dmx channels and control everything with

Martin LightJockey 2

all effects lights are (not including stage lights)

2 – American DJ Galaxian 3d Red/Green laser Lights

2 – American DJ Jellydomes

2 – American DJ Starball LED DMX

6 – CHAUVET COLORSTRIP LED BAR – (38 inch)

3 – CHAUVET COLORSTRIP MINI LED BAR – (19inch)

3 – Blizzard Lighting The PUCK (RGB vesion)

7 – American DJ Pinspot LED

2 – American DJ Fusion Tri FX Bar

2 – American DJ Fusion FX Bar 2

2 – American DJ Fusion FX Bar 3

2 – American DJ Fusion FX Bar 4

4 – Chauvet MiN Spot RGB led moving heads

1 – DivineLighting.com LED Hyper Panel 288 RGBAW

2 – CHAUVET COLORdash Batten

2 – 36, 1-watt led, RGB moving head wash(generic brand)

This is inspiring. My church is about to start building sets for our kids ministry. I’m hoping to do something like this, but probably not quite as intricate.

Thanks!

Great set!

I have a question related to the lights – you seem to be using some smaller fixtures with really focussed beams at the base of the stage – what are they – been looking for something like that!!

these are the lights we use to get the focused beams you are talking about:

2 – American DJ Fusion Tri FX Bar (red gren and blue beams)

2 – American DJ Fusion FX Bar 3 (just whitebeams)

if you want additional beam direction-options, AND you do not need the wash leds that come with these effects, you could buy a ton of these:

American DJ Pinspot LED

they are the same brightness and come with 2 lens options so you can choose your beam angle… we use 7 in our set to make a semi-circular cone tunnel (with fog)

They work great.

Just hook them to a powerstrip or dmx RELAY-pack

You guys WOULD be the favorite of the month…LOL…MISS YOU GUYS!!!!!

Are your circular screens just projected? Do they have custom graphics or just masking on the projectors?

we are using custom graphics that are “pre-masked” in After Effects before final render.

since we are using rear-view projection, this is not a necessary step, just to keep things neat & tidy

for the first couple months of the tour, I just projected unmasked content. (4×3 signal)

but it does clean up the edges to run a consistent mask.

After years, i can still remember this stage design. This is one of my dream (peg) stage design. We are looking forward for the day we can use metal and other materials used in this stage design.